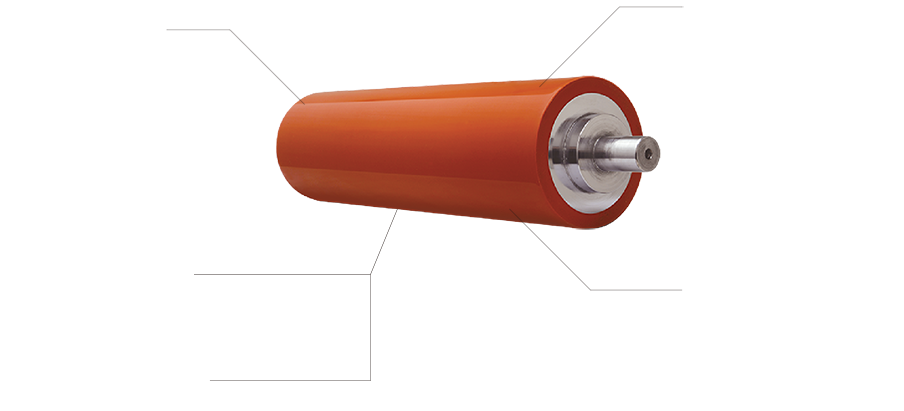

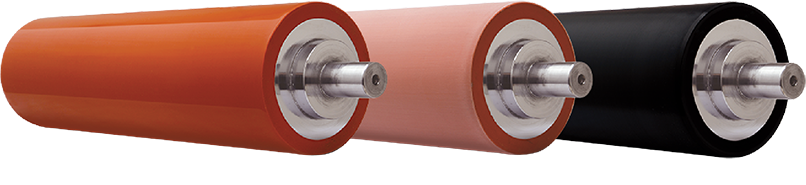

Fluororesin-Coated Rolls FST Roll

Elastic rubber rolls coated with fluororesin, heat-shrinkable tubes used in our original manufacturing technology enables adhesion processing of base materials and fluororesin at the same time as shrinking processing. Accordingly, “distortion”, “wrinkle”, “gap” can be eliminated on the roll even when shrinking-processed.

Application

- Olefin sheeting roll

- Laminating roll

- AC agent coating backup roll

Features

■Excellent mold releasability

Base material (rubber/metal) coated with fluororesin (PFA or FEP) is excellent in mold release effect, preventing adhesion of viscous material, resin, etc. Shows excellent mold release effect for molten olefin.

■Elastic rubber rolls coated with fluororesin, heat-shrinkable tubes.

Our original manufacturing technology enables adhesion processing of base materials and fluororesin at the same time as shrinking processing. Accordingly, “distortion”, “wrinkle”, “gap” can be eliminated on the roll even when shrinking-processed.

■Excellent solvent resistance

Fluorine resin has an excellent resistance to almost all solvents, so there is no swelling problem as found in general rubber rolls.

■Precision polishing available

Polishing equivalent to general elastic rolls is possible.

■Conductive type also available.

The volume resistivity of the roll is 1.0×107Ω・cm or less.

Roll type

Roll surface

-

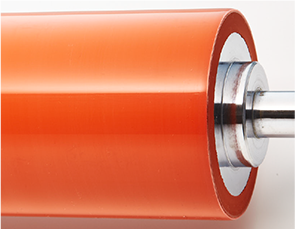

■Mirror finish -

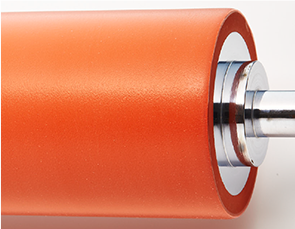

■Semi-matte finish -

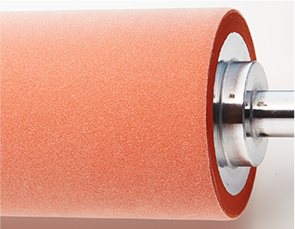

■Matte finish

Surface finish specification

“Special surface treatment finish” allows adjustment of surface roughness suitable for your application

■Regular finish

| Specification | B finish | A finish | Special A finish |

|---|---|---|---|

| Surface roughness (Ra) | 1.1μm or less | 0.7μm or less | 0.4μm or less |

* The above data are not standard values

■Surface roughness (Ra)

| Specification | Mirror finish | Semi-matte finish | Matte finish |

|---|---|---|---|

| Surface roughness (Ra) | 0.1μm or less | 0.4~3.0μm | 0.4~6.0μm |

* The above data are not standard values

Process examples

-

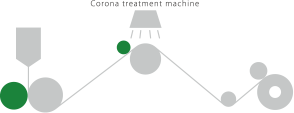

■T-die sheeting process example

-

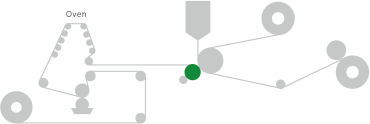

■T-die laminating process example

-

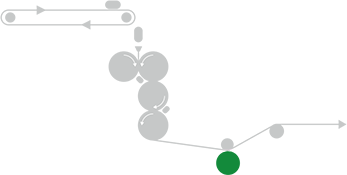

■Calendar sheeting process example

-

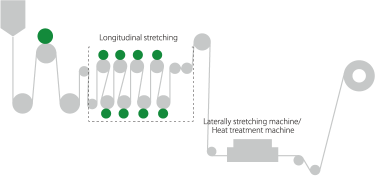

■Longitudinal stretching process example