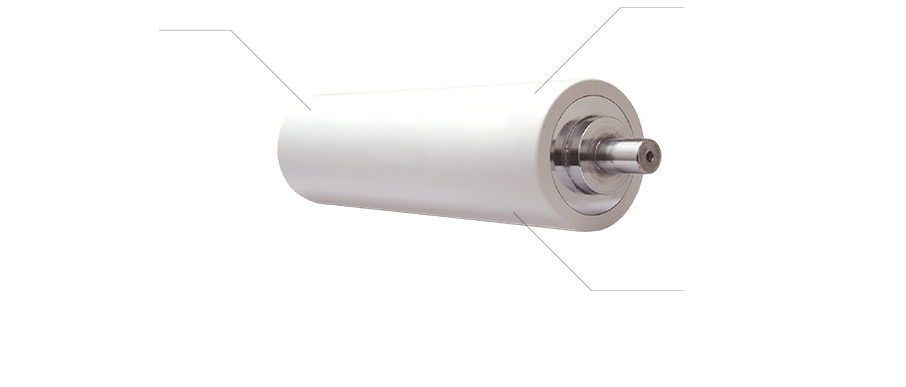

Low Friction Silicone Rubber Rolls IT68S-KS

Original and special silicone surface treatment called KS treatment provides “slidability” and “mold releasability” to various roll base materials.

Application

- Touch roll

Features

■Processing on various base material

Our original compound enables processing on various industrial rolls, including metals and synthetic rubbers (EPT/NBR), etc.

■Low friction silicone rubber

Although it is silicone rubber, it exhibits the same slipperiness as fluorine resin, which is a typical low friction material.

■Prevents static electricity

It suppresses static electricity generated by the grip of rubber and prevents “wrinkle generation” and “film removal”.

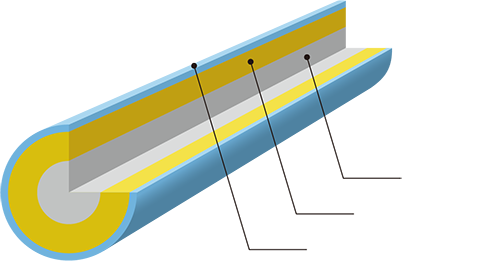

Structure

Base material (metal core)

Rubber

KS

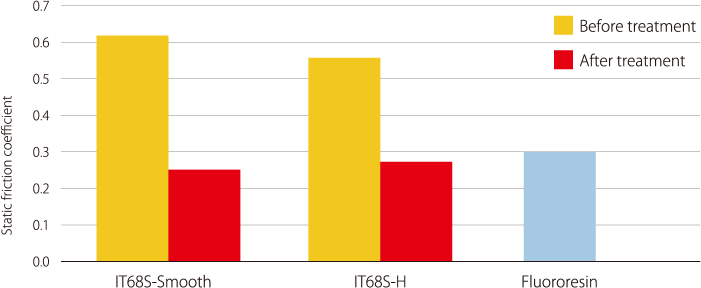

Comparison of friction coefficient

By applying KS treatment to silicone rubber, which is a material with high grip properties, it will have the same level of slipperiness (friction coefficient) as fluorine resin.

※Measured with Shinto Scientific., Ltd.’s HEIDON Tribogear Muse Type 94i-II

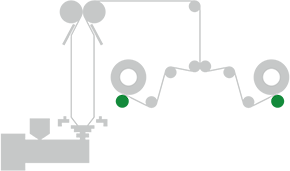

Process examples

-

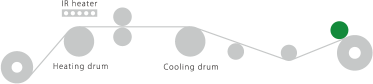

■T-die sheeting process example

-

■T-die laminating process example

-

■Embosser process example

-

■Inflation process example