RTV Silicone Rubber Rolls IT68S-Matte

The roll is lined with silicone rubber RTV (Room Temperature Vulcanizing).

Allows adjustment of surface roughness depending on your application.

Application

- Sheeting roll

- Embossed roll

- Embossed back roll

Features

■Seamless processing

No processing traces such as seams that occur during general rubber molding.

■Liquid RTV (Room Temperature Vulcanizing) silicone rubber

■Compound design suitable for each application

■Excellent mold releasability and heat resistance

Since the material is silicone rubber, it has excellent mold release effect and heat resistance.

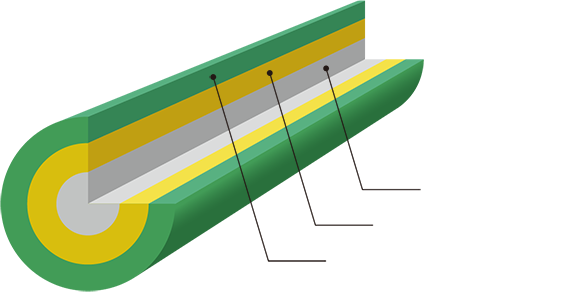

Structure

Base material (metal core)

Intermediate layer : IT68S-H or Synthetic rubber

Outer layer : IT68S-Smooth

Metal core bar can be bonded as is or can be bonded with a synthetic rubber (EPT/NBR) layer.

New surface layer re-installation is available (rewinding).

Standard of surface roughness

| Particle size | IT68S-Smooth | ♯240 | ♯280 | ♯320 | ♯400 | ♯500 |

|---|---|---|---|---|---|---|

| Surface roughness (Ra) | 1.2±0.5μm | 5.0±2μm | 4.5±2μm | 4.0±2μm | 3.0±1μm | 2.5±1μm |

| Particle size | ♯600 | ♯700 | ♯800 | ♯1000 | ♯1200 | ♯1500 |

|---|---|---|---|---|---|---|

| Surface roughness (Ra) | 2.0±1μm | 1.8±0.5μm | 1.5±0.5μm | 1.3±0.5μm | 1.3±0.5μm | 1.3±0.5μm |

※Complies with JIS B 0601

Process examples

-

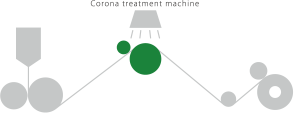

■T-die sheeting process example

-

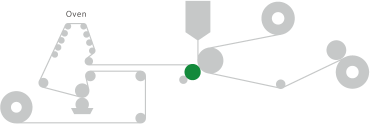

■T-die laminating process example

-

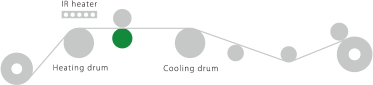

■Embosser process example

-

■Calendar sheeting process example