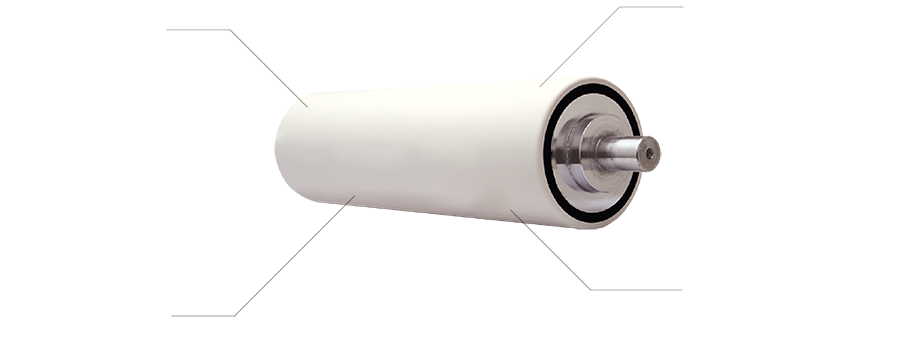

RTV Silicone Rubber Rolls IT68S-Smooth

The roll is lined with silicone rubber RTV (Room Temperature Vulcanizing).

Allows adjustment of compound and rubber hardness depending on your application.

Application

- Sheeting roll

- Embossed roll

- Embossed back roll

Features

■Seamless processing

No processing traces such as seams that occur during general rubber molding.

■Liquid RTV (Room Temperature Vulcanizing) silicone rubber

■Compound design suitable for each application

■Excellent mold releasability and heat resistance

Since the material is silicone rubber, it has excellent mold release effect and heat resistance.

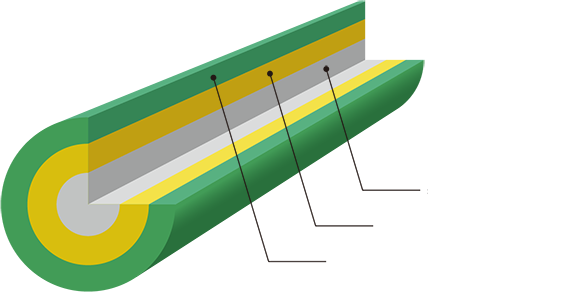

Structure

Base material (metal core)

Intermediate layer : IT68S-H or Synthetic rubber

Outer layer : IT68S-Smooth

Metal core bar can be bonded as is or can be bonded with a synthetic rubber (EPT/NBR) layer.

New surface layer re-installation is available (rewinding).

Compound design suitable for each application

| Compound | Normal compound |

Mold releasable compound |

High mold releasable compound |

High strength compound |

Abrasion resistance compound |

|---|---|---|---|---|---|

| Hardness Durometer A |

40~85 | 50~80 | 50~75 | 40~80 | 40~80 |

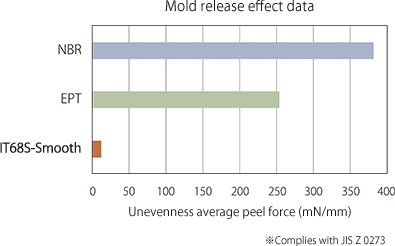

IT68S-Smooth

Silicone rubber is a material with superior mold release effect compared to EPT and NBR.

Among them, the RTV silicone rubber used in IT68S-Smooth is a rubber with an excellent mold release effect compounding.

Process examples

-

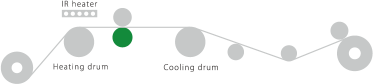

■T-die sheeting process example

-

■T-die laminating process example

-

■Embosser process example

-

■Calendar sheeting process example